- 등록2017.09.15 15:53:42

Axial displacements of cemented prosthesis in

external and internal implant-abutment connection

Introduction

Axial displacement is a unique biomechanical feature of internal conical connection (ICC) implants. ICC abutments lacking structures for vertical stop might sink axially into the inner surface of the implant. Axial displacement of abutments causes several mechanical problems in ICC implants.

Axial displacement might occur during screw tightening or occlusal loading. The wedge effect of the abutment increases with the increase in tightening torque, resulting in a tight connection at the implant?abutment connection.

Custom CAD/CAM abutments might have greater machining tolerance than ready-made abutments. Moreover, in comparison ready-made abutments, they possess different and less-controlled surface roughness. Differences in fit of implant?abutment connection are expected to result in differences in axial displacement.

The purpose of this study was to quantitatively evaluate axial displacement in three different implant?abutment connections in cement-retained monolithic zirconia and PMMA provisional prostheses with CAD/CAM custom abutments.

Material and methods

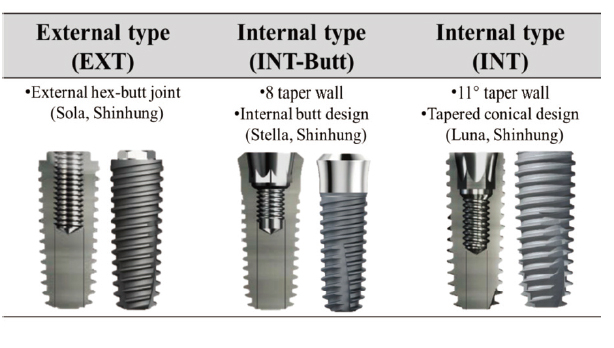

Three types of implants with different connections were evaluated

: External butt connection, internal butt connection, and

internal conical connection implant

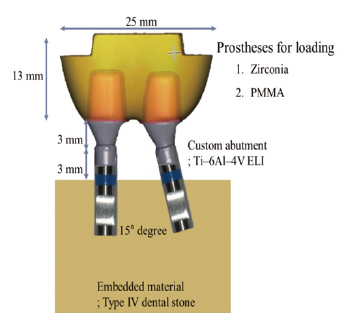

In each implant group, implant replicas were embedded vertically and angulated at 15°.

In each implant group, implant replicas were embedded vertically and angulated at 15°.

Sixty titanium custom abutments were fabricated using a computer aided design?computer aided manufacturing system

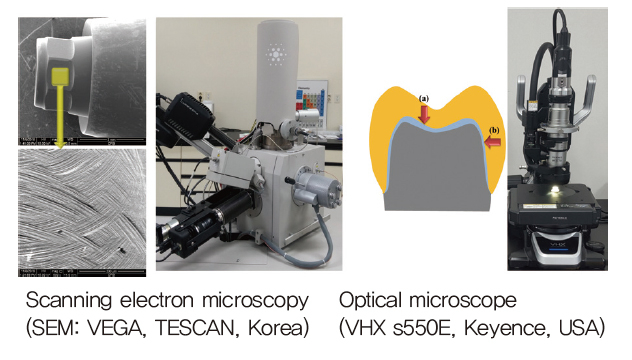

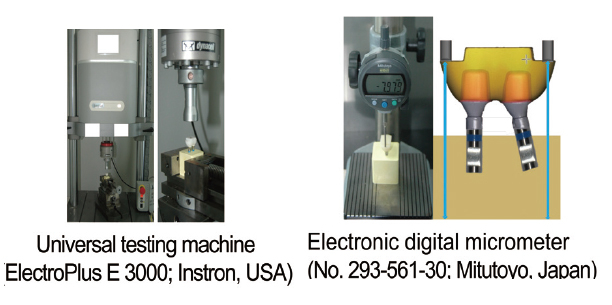

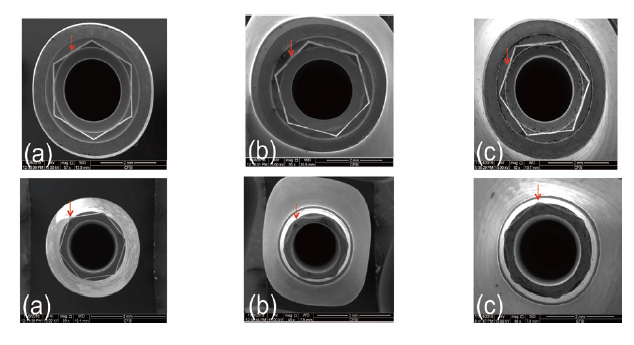

The geometries and surface morphologies of custom and ready-made abutments were comparatively evaluated by scanning electron microscopy. Micro-gaps in abutment connection were scanned by optical microscopy during screw tightening, re-tightening, and cyclic loading. Zirconia and provisional acrylic prostheses were fabricated and evaluated for internal gap by an indirect silicone technique.

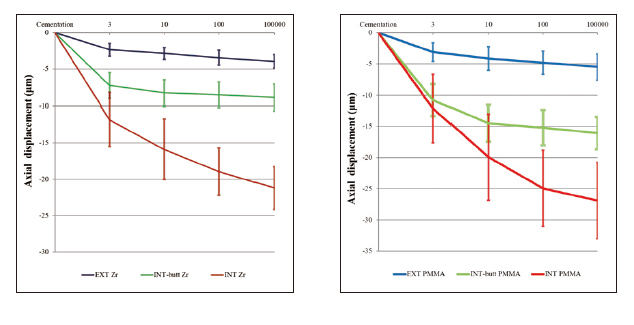

Cemented prostheses on abutments were mounted on a universal testing machine and subjected to 250 N sine wave cyclic loads. Cumulative axial displacement was measured at loading periods of 3, 10, 100, and 106 and analyzed by repeated measures analysis of variance (ANOVA). Internal gap width and net change in axial displacement were analyzed by multi-way ANOVA.

Result

The internal and external conical connection implants exhibited the greatest and lowest axial displacements, respectively.

Machining tolerance control and precision fit were difficult to achieve with the custom CAD/CAM abutment.

(a) Shinhung ready-made abutment

(a) Shinhung ready-made abutment

(b) E-pros custom abutment

(c) Ti block custom abutment

The vertically positioned implant group exhibited greater axial displacement than the angulated implant group in the early cyclic loading periods. Axial displacement in the late cyclic loading period was relatively low.

Conclusion

Custom abutments for cement-retained prostheses exhibited greater axial displacement than screw-retained prostheses. Axial displacement mostly occurred in the early loading period and was self-limited. Axial displacement should be managed by provisional restoration, with consideration of implant connection type and angulation, abutment fabrication method, and occlusal force of the patient.

Reference

Lee JH, Kim DG, Park CJ, Cho LR. Axial displacements in external and internal implant-abutment connection. Clin Oral Implants Res 2014;25(2):e83-9

Ricciardi Coppede A, de Mattos Mda G, Rodrigues RC, Ribeiro RF. Effect of repeated torque/mechanical loading cycles on two different abutment types in implants with internal tapered connections: an in vitro study. Clin Oral Implants Res 2009;20(6):624-32.

Cho WR, Huh YH, Park CJ, Cho LR. Effect of cyclic loading and retightening on reverse torque value

in external and internal implants. J Adv Prosthodont 2015;7(4):288-93.

Copyright @2013 치의신보 Corp. All rights reserved.